A Guide to Selecting Sand Pumps for Dredgers: Six Core Parameters for Precise Matching of Requirements

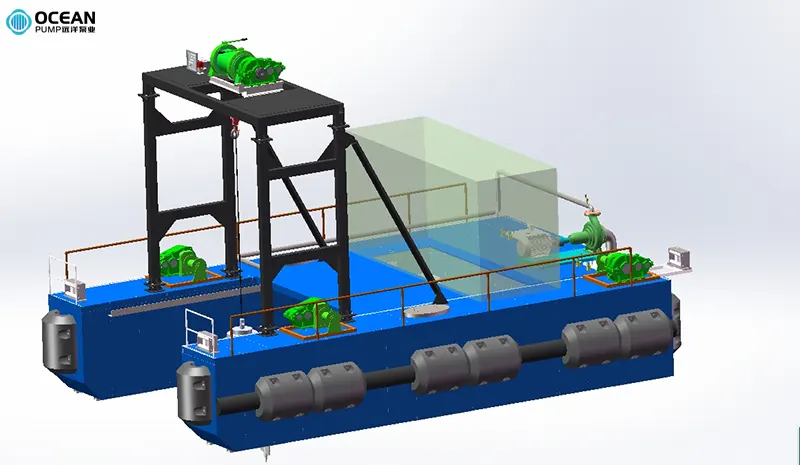

In dredging projects, the sand pump serves as the "heart" of a dredger, and its performance directly determines dredging efficiency, operational costs, and equipment lifespan. Whether configuring a sand pump for a new sand suction dredger or upgrading/replacing the sand pump of an old dredger, neglecting the matching of key parameters can lead to minor issues such as soaring energy consumption and frequent component damage, or even major problems like the paralysis of the entire dredging system. Starting from actual project needs, this article breaks down six core selection parameters to help you avoid selection mistakes and choose a sand pump with strong adaptability and high cost-effectiveness.

1. Flow Rate: The Core Indicator for Anchoring Dredging Efficiency

The flow rate of a sand pump (measured in m³/h or GPM) represents the volume of slurry that can be transported per unit time, serving as the foundation for measuring dredging capacity. If the flow rate is disconnected from project requirements during selection, two extreme problems may occur: insufficient flow rate will make it impossible to meet the target of sediment removal, while excessive flow rate will result in wasted power and may even accelerate wear due to overly high slurry flow velocity in the pipeline.

Key Points for Precise Selection:

- 1.Align with project objectives: Calculate the required flow rate based on the "daily sediment removal volume" and "dredging cycle" specified in the contract. For example, if 5,000 m³ of sediment needs to be removed daily and the daily operation lasts 10 hours, a sand pump with a flow rate of no less than 500 m³/h should be selected (a 10%-15% redundancy should be reserved to cope with fluctuations in slurry concentration).

- 2.Adapt to slurry concentration: In actual dredging, the solid content of slurry is usually 15%-20% (i.e., 1 cubic meter of slurry contains 0.15-0.2 cubic meters of dry sand). If the sand pump is selected solely based on the marked clear water flow rate, the actual transportation capacity will decrease due to the high density of the slurry. Therefore, it is necessary to choose equipment with a "slurry flow rate" that meets the requirements, rather than just focusing on the clear water flow rate.

- 3.Avoid imbalance in retrofitting: When replacing the pump of an old dredger, the flow rate of the original sand pump should be used as a benchmark. If the flow rate of the new pump far exceeds the carrying capacity of the original pipeline, it will cause pipeline vibration and interface leakage; if the flow rate is too low, it will lead to slurry deposition in the pipeline and blockage.

2. Total Dynamic Head (TDH): The Key to Overcoming System Resistance

Total Dynamic Head refers to the energy required by the sand pump to overcome "vertical lift + pipeline friction + velocity loss". Insufficient TDH will prevent the slurry from reaching the designated discharge point, while excessive TDH will result in wasted power and even damage to pipeline valves. In many projects, the phenomenon that "the sand pump seems to have a qualified flow rate but cannot transport the material far" is essentially caused by improper TDH selection.

Scientific Calculation Methods:

- 1.Accurately calculate the static lift: Measure the vertical height difference between the sand pump's suction port and the discharge port (e.g., if the sand pump is installed on the dredger deck and the discharge port is connected to a 5-meter-high sediment pile on the shore, the static lift is 5 meters), which is the basic component of TDH.

- 2.Quantify friction loss: Calculate based on the pipeline length, diameter, and material. For example, for a 100-meter-long steel pipe with a diameter of 300 mm, the friction coefficient is approximately 0.02. If the slurry flow velocity is 2 m/s, the friction loss of a single section of the pipeline is about 8 meters; if the pipeline contains 3 900 elbows, each elbow will require an additional 1.5 meters of head loss (adjustments should be made according to different pipeline materials and the number of elbows).

- 3.Match the flow rate and head curve: High-quality sand pumps provide a "flow rate-head curve". During selection, ensure that the head value corresponding to the "target flow rate" is greater than the total dynamic head of the system (e.g., if the calculated TDH of the system is 25 meters, a sand pump with a head of no less than 30 meters at the target flow rate should be selected, with a safety margin reserved).

Retrofitting Reminder: If the pipeline layout of an old dredger is adjusted (e.g., extending the discharge distance or adding elbows), the TDH must be recalculated. The head parameters of the original sand pump cannot be directly used. In one project, the TDH was not recalculated after retrofitting, and the new pump could only transport the slurry to 60% of the original distance due to insufficient head. Eventually, an additional booster pump had to be installed, increasing the cost.

3. Power Supply: Avoid "Overpowered Motors for Small Loads" or "Underpowered Motors for Heavy Loads"

The sand pump is powered by the dredger's prime mover (diesel engine or electric motor). Mismatched power will not only prevent the sand pump from operating at full load but also burn out the motor or damage the prime mover in severe cases.

Key Points for Adaptation:

- 1.Power should not exceed the limit: The rated power of the new sand pump must be ¡Ü the rated output power of the prime mover (e.g., if the prime mover is 150 kW, the power of the new sand pump should be controlled within 130 kW, with a 13% redundancy reserved to cope with the power peak during startup).

- 2.Strict speed synchronization: The shaft speed of the sand pump must be consistent with the output speed of the prime mover, with a tolerance of -5% - 5%. For example, if the output speed of the prime mover is 1450 r/min, the speed of the new sand pump should be between 1378-1523 r/min. Forcibly adjusting the speed through pulleys due to speed mismatch will accelerate the wear of the sand pump impeller and reduce its service life by more than 50%.

- 3.Compatibility of control systems: If the original dredger is equipped with a Variable Frequency Drive (VFD), ensure that the motor of the new sand pump supports frequency conversion adjustment and that its rated voltage and current are consistent with the output parameters of the VFD. If manual throttle control is used, ensure that the inlet and outlet valves of the new sand pump can be connected to the original control mechanism to avoid operational failure due to control incompatibility.

4. Pipeline Configuration: Enabling "Seamless Collaboration" Between the Sand Pump and Pipeline

The sand pump and pipeline work as an integrated "series system". Even if the sand pump has excellent performance, it cannot function properly if the pipeline parameters do not match the sand pump. In many projects, problems such as "fluctuating flow rate" and "pipeline abnormal noise" occur after the installation of a new sand pump, mostly due to improper pipeline configuration.

Key Matching Principles:

- 1.Strict diameter correspondence: The suction port diameter and discharge port diameter of the sand pump must be completely consistent with the inner diameter of the original pipeline (e.g., if the suction port diameter of the sand pump is 350 mm, the inner diameter of the pipeline should also be 350 mm). If the pipeline diameter is smaller than the sand pump interface, it will increase the suction resistance and cause "cavitation"; if the pipeline diameter is too large, it will reduce the slurry flow velocity and lead to sediment deposition and blockage.

- 2.Balance wear resistance and efficiency in material selection: For transporting high-hardness quartz sand, rubber-lined or wear-resistant steel pipelines should be selected (their wear resistance is 3-5 times higher than that of ordinary steel pipes). If the sediment to be transported has a high mud content and low hardness, ordinary steel pipes can be used to balance cost and efficiency.

- 3.Adapt the layout to the existing structure: The pipelines of old dredgers are mostly fixed on the hull frame. When replacing the sand pump, confirm that the positions (horizontal/vertical) of the suction and discharge interfaces of the new pump are consistent with the pipeline direction. For example, if the original pipeline is connected to the sand pump horizontally, but the new pump has a vertical interface, additional elbows must be installed, which not only increases friction loss but also occupies more installation space.

5. Physical Installation: Addressing the Issue of "Easy Installation and Maintenance"

In many projects, only the performance of the sand pump is considered during selection, while installation space and maintenance convenience are ignored. This leads to problems such as the new pump "being unable to be installed" after being delivered to the site, or "being difficult to disassemble and replace" during subsequent maintenance, seriously affecting operational efficiency.

Key Points for Installation and Maintenance Adaptation:

- 1.Precise matching of base dimensions: Measure the length, width, and installation bolt hole spacing of the original sand pump's base. The base of the new pump must be completely consistent (with an error ¡Ü 2 mm) to avoid prolonged installation cycles caused by the need to re-weld steel plates due to base mismatch.

- 2.No conflict in interface direction: Confirm that the orientation of the suction and discharge interfaces of the new pump (e.g., suction port facing left, discharge port facing upward) corresponds to the position of the original pipeline interface. Excessive deviation in interface direction will require extensive pipeline adjustments, which not only increases costs but also may damage the hull structure.

- 3.Reserve sufficient maintenance space: Regular replacement of the impeller and mechanical seal is required during the operation of the sand pump. During selection, ensure that there is sufficient operating space around the pump body. For example, at least 1.5 times the impeller diameter of space is required for impeller disassembly, and an operating distance of more than 0.8 meters is reserved for mechanical seal replacement to avoid doubling the maintenance time due to narrow space.

Practical Suggestion: Request a 3D model of the sand pump from the manufacturer and conduct collision detection with the CAD model of the dredger's installation area to identify spatial conflicts in advance.

6. Cost Considerations: Calculating the "Full-Life Cycle Cost"

The selection of a sand pump should not only focus on the "purchase price" but also comprehensively evaluate the initial investment, operational costs, and maintenance costs to choose equipment with "reasonable short-term investment and controllable long-term costs". In many projects, low-quality sand pumps are chosen for low purchase prices. Although the purchase cost is saved, the total cost ultimately increases by 2-3 times due to frequent replacement of wearing parts, high energy consumption, and long downtime.

Cost Optimization Strategies:

- 1.Initial investment: Prioritize sand pumps with a "modular design". For example, the motor, impeller, and seals can be replaced individually. If performance upgrades are needed later, only the corresponding components need to be replaced, rather than replacing the entire pump, reducing long-term retrofitting costs.

- 2.Operational costs: Compare the "energy consumption per unit of transported slurry" of sand pumps (e.g., how many kWh of electricity are consumed to transport 1 m³ of slurry). Choose equipment with low energy consumption (high-quality sand pumps consume 15%-20% less energy than low-quality ones, which can save tens of thousands of yuan in electricity costs annually based on 10 hours of daily operation).

- 3.Maintenance costs: Select sand pumps with highly versatile wearing parts and easy replacement. For example, the impeller adopts a standardized design and can be purchased in the local market without procuring from the original factory, shortening the replacement cycle; the mechanical seal adopts a "cartridge type", which reduces the replacement time by half compared with traditional seals and minimizes downtime losses.

Three "Hidden" Precautions for Sand Pump Replacement

For the sand pump retrofitting of old dredgers, in addition to the six parameters mentioned above, three easily overlooked details should also be paid attention to to avoid "affecting the whole system with a single change":

- 1.Adaptation of seals and bearings: The inner diameter of the mechanical seal must be completely consistent with the shaft diameter of the sand pump. A deviation in seal size will cause slurry leakage. The lubrication method of the bearing (oil lubrication/grease lubrication) must match the original maintenance process. For example, if the original equipment uses grease lubrication, changing to oil lubrication for the new pump will require additional installation of an oil tank and oil circuit, increasing maintenance complexity.

- 2.Docking of monitoring systems: The output signals (e.g., 4-20 mA current signals) of the pressure sensor and temperature sensor of the new sand pump must be compatible with the dredger's central control system. This ensures that operators can monitor the operating status of the sand pump in real-time and avoid failure to warn of faults due to signal mismatch.

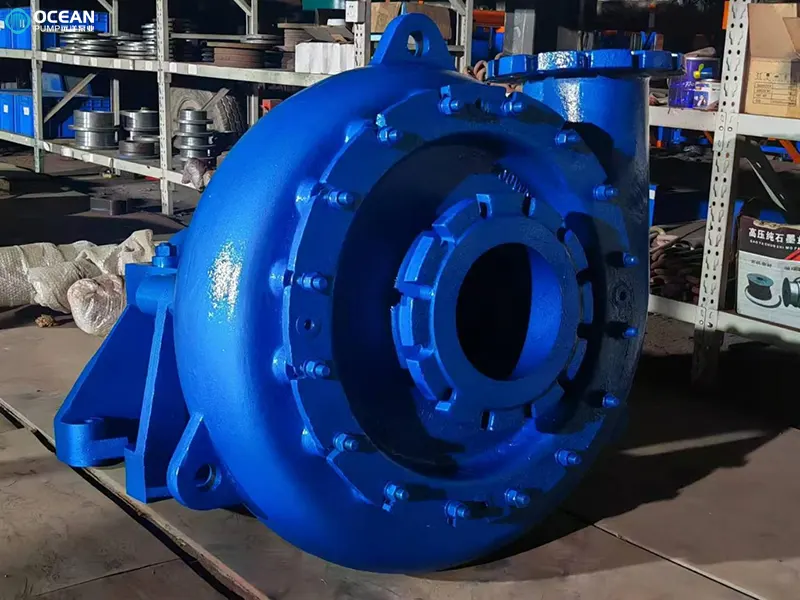

- 3.Wear resistance enhancement: If the sediment in the dredging area has a high silica content (e.g., quartz sand content exceeds 30%), a sand pump with impellers and pump casings made of Cr27 wear-resistant alloy should be selected. Its wear resistance is 5-8 times that of ordinary cast iron, which can extend the impeller replacement cycle from 1 month to more than 6 months.

Conclusion: No Detail Is Trivial in Selection, and Details Determine Success or Failure

The selection of a sand pump for a dredger is a "systematic project" that requires considering performance, compatibility, cost, and maintenance convenience. A deviation in any parameter may lead to reduced project efficiency and cost overruns. It is recommended to collect data such as the prime mover parameters, pipeline drawings, and project dredging requirements of the dredger before selection, and cooperate with professional sand pump manufacturers to verify the selection plan through hydraulic simulation software, ensuring that the sand pump is accurately matched with the entire dredging system. Only by selecting the right sand pump can the dredger maximize its efficiency and achieve dual improvements in project benefits and equipment lifespan.

Details working project welcome contact:

TAIAN OCEAN PUMP CO.,LTD

WHATSAPP :+86 18562293319

EMAIL : oc@tsbeng.com

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19