Application of Slurry Pumps in Dredging Projects

In recent years, in response to environmental protection calls, environmental remediation efforts have been carried out in an orderly manner across various regions. This includes dredging and desilting of rivers, expansion and desilting of fish ponds, and cleaning of sedimentation tanks in industrial enterprises. Dredging, as an important part of water conservancy projects, generally involves using mechanical equipment¡ªmost notably, slurry pumps¡ªto stir up deposited silt into a muddy liquid. This liquid is then conveyed to designated disposal sites through the rotation of the pump's impeller, achieving the goal of unblocking and cleaning.

Slurry pumps come in a wide variety of types. Structurally, they can be divided into horizontal, vertical, and submersible slurry pumps. Functionally, they include large-particle slurry pumps, multi-purpose slurry pumps, and amphibious (both ship and land) slurry pumps. Different types of slurry pumps, based on their structural characteristics, are suitable for various dredging scenarios. Sometimes, multiple types of slurry pumps are combined in the same project to collectively complete the dredging tasks. Slurry pumps are known for their high efficiency, low investment, and flexible operation, making them widely used in dredging and desilting projects for rivers, ponds, and other water bodies. Common dredging schemes include combinations of grab buckets with slurry pumps, vertical and horizontal slurry pumps, and dredging vessels with slurry pumps. Haichuan Pump Industry provides a brief introduction to the application of slurry pumps in dredging projects for reference by users.

I. River Dredging and Its Significance

Many cities, especially those in the south, have numerous and crisscrossing urban rivers. In recent years, due to decreased rainfall and lowered groundwater levels, many rivers have dried up, leading to silt accumulation. Some rivers are also polluted by large amounts of domestic waste, causing environmental problems and affecting residents' lives. River siltation has severely impacted functions such as flood prevention, drainage, irrigation, water supply, and navigation. Therefore, carrying out river dredging projects to restore river functions is of great significance for promoting rapid and sustainable socio-economic development.

Through dredging, the amount of silt in rivers can be effectively reduced, the flood discharge capacity of embankments can be enhanced, and rivers can become deeper and wider with clearer water. This significantly improves the living and production conditions of the public and achieves the goal of "clear water, smooth rivers, green banks, and beautiful scenery."

There are two specific construction environments for river dredging:

Rivers with Little Water Flow: In this case, the water in the river is drained, and a cofferdam is built. A hydraulic reclamation unit composed of a vertical slurry pump and high-pressure water gun is then used for dredging operations.

Rivers with Significant Water Flow: In this scenario, a dredging vessel equipped with a slurry pump is used for dredging. The choice between these methods mainly depends on the local technical and economic conditions. In both cases, slurry pumps are key to completing the dredging operations.

II. Preparations for River Dredging

Before river dredging operations, construction companies need to organize professional technical personnel to conduct a comprehensive survey of the construction site and accurately calculate the project volume. Based on the construction drawings, including the construction period and the types and quantities of equipment needed, corresponding auxiliary work should be carried out. The slurry pump is a key piece of equipment in river dredging, with auxiliary equipment such as bulldozers and excavators. Construction units need to pay special attention to the following issues:

Clarify the requirements of the construction drawings, understand the river cross-section conditions, including water quality and the main components of the silt.

Reasonably inspect the bridges and culverts at the construction site. Based on the load-bearing capacity of the bridges, optimize the construction equipment.

Check whether there is a stable power supply at the construction site. Generally, water-lifting stations around the river can be used for power supply. During the layout of the power transmission lines, the specific direction and length of the lines should be determined.

Confirm the water source needed for the slurry construction process. The original river water can be effectively utilized to ensure the recycling of water resources.

Clarify the specific location for silt disposal, including the topography of the disposal site.

Determine the specific location of the construction command post and whether river ditches can be used to effectively treat the sedimented water in the slurry pond.

Clarify the specific location of the construction shed to choose a reasonable river dredging process.

III. Dredging Construction Schemes

River dredging and desilting construction is highly systematic. Before construction, construction units need to develop a scientific construction plan based on hydrogeological data and prepare sufficient materials and equipment according to the specific conditions of the construction site.

I. Grab Bucket Construction Scheme

Construction personnel can use a grab bucket dredger to effectively excavate the silt at the riverbed. The specific construction process is as follows:

Insert the grab bucket at the front of the dredging vessel into the riverbed. The insertion depth should be significant. After the grab bucket reaches the bottom of the mud, close the grab bucket promptly and lift it.

Transfer the silt inside the grab bucket into the mud barge.

Through multiple cycles, the river silt is effectively cleaned.

This construction process is applied to rivers with a thicker layer of mud and can achieve better application results. In actual construction, workers need to determine the thickness of the river mud layer and completely remove obstacles in the river to continuously improve the efficiency of river dredging and shorten the working time.

II. Slurry Pump Construction Scheme

Vertical Slurry Pump for River Dredging

Working Principle and Construction Scheme

The vertical slurry pump adopts a combination of hydraulic flushing and manual excavation. The hydraulic flushing unit consists of three parts: a high-pressure pump, a vertical slurry pump, and a power distribution system. The equipment is lightweight, easy to assemble, and convenient for operation. Its working principle simulates the natural phenomenon of water flow erosion. High-pressure water flow is used to cut and crush the soil, forming a slurry that is then conveyed to the spoil area for sedimentation by the slurry pump. The hydraulic flushing unit mainly includes a vertical slurry conveying system, a water flushing system, and a power distribution box system. Each unit consists of one slurry pump, one high-pressure water pump, and two high-pressure water guns.

Features of Vertical Slurry Pump

(1) Simple mechanical principle, easy installation and disassembly, lightweight pump body, and convenient operation.

(2) Low equipment cost and minimal overall investment.

(3) Open impeller design with good passability, capable of easily sucking up mud lumps, garbage, or large solid particles without clogging.

(4) The pump operates below the water level, eliminating the need for priming, with strong suction and high slurry concentration.

(5) The over-flow components can be made of wear-resistant cast iron or high-chromium alloy materials, which are hard, strong, and resistant to wear. The service life is 2-3 times longer than that of ordinary materials.

Construction Precautions

(1) The working position of the slurry pump should be deeper than the flushing point, with a depth of no less than 0.5 meters, to accelerate the slurry flow rate and increase the mud content.

(2) The distance between the slurry pump and the flushed soil body should not be too far. Generally, it should not exceed 10 meters to prevent debris from damaging the equipment.

(3) A rapid flow channel should be provided for the slurry to flow towards the suction port. The distance between the water gun operator and the excavation surface should be 3-5 meters for optimal efficiency.

(4) When flushing the slope soil, the angle between the water jet and the slope surface should not exceed 15 degrees, and the angle should approach zero during slope trimming.

(5) Each working section should meet the standard at one time. Only after the engineer's approval can the slurry pump be moved to the next section for flushing operations.

(6) For various working dams, they should be flushed and dismantled in time as the project progresses.

(7) The slurry conveying pipeline should be straight and flat, with gentle bends. The entire pipeline must not leak slurry or water, and the joints should be tightly secured.

The vertical slurry pump is suitable for simple projects but has low flow and head, with a short conveying distance. For large-scale projects with tight schedules, long conveying distances, and harsh environments, it is more common to use horizontal slurry pumps in series to form a pumping cluster for dredging operations.

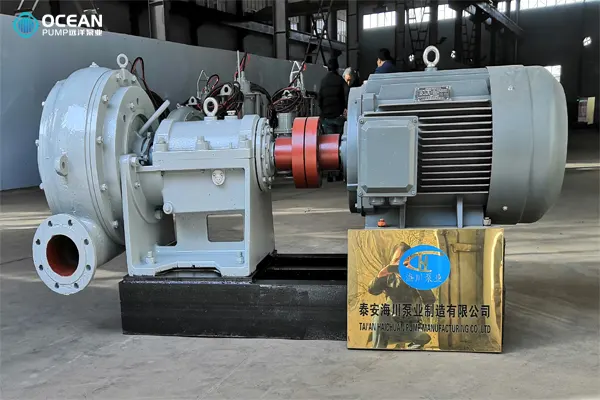

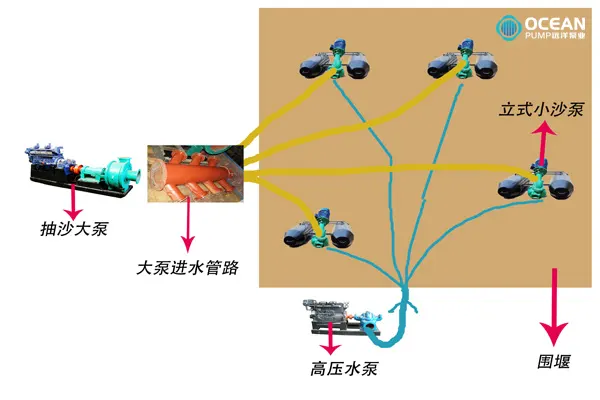

Combination of Vertical and Horizontal Slurry Pumps for Dredging

(1) Construction Principle

Multiple vertical slurry pumps and high-pressure water pumps form a hydraulic reclamation unit that flushes the deposited silt in the river into a slurry. The slurry is then sucked up by the vertical slurry pump and collected in a horizontal slurry pump, which conveys it through pipelines to the spoil site. The horizontal slurry pump has a large flow rate and high head, making it suitable for long-distance conveyance. Its over-flow components are made of highly wear-resistant materials, which reduce wear frequency and improve work efficiency.

(2) Features of Horizontal Slurry Pump

(1) Wide range of applications, can be equipped with diesel engines, electric motors, or hydraulic units, suitable for various complex working conditions.

(2) High efficiency and energy-saving, single-shell structure, wide impeller flow channel, and four-blade design for high efficiency.

(3) Reliable operation, standardized design drawings, packing seal form that is simple to replace, oil-lubricated, and advanced structure.

(4) High wear resistance, over-flow components made of high-quality high-chromium alloy material (Cr28), and standard parts selected from the best domestic brands.

III. Dredging Vessel Construction Scheme

Introduction to Dredging Vessels

A dredging vessel is a device that stirs up mud and sand through a digging system and then extracts it using a slurry pump. The vessel is equipped with a slurry pump and a drive system, which extracts mud and sand through pipelines and transports it to designated locations. This type of equipment is widely used in large-scale land reclamation projects from the sea and is divided into cutter suction, trailing suction, and bucket-wheel types. Dredging vessels originated in the Netherlands, and to this day, 80% of the world's large dredging vessel orders are still placed in the Netherlands. China has also manufactured the world's largest and most advanced dredging vessels. Dredging vessels come in large, medium, and small sizes. Due to the limitations of sea waves and water depth, medium and large dredging vessels are generally used for land reclamation.

Configuration of Slurry Pumps for Dredging Vessels

Medium and large dredging vessels are usually equipped with two slurry pumps, one for suction and one for discharge. The suction pump is chosen for its larger flow rate to enhance the transportation capacity of mud and sand. The discharge pump is selected for its higher head to meet the requirements of long-distance conveyance. For deeper excavation scenarios, underwater slurry pumps are also equipped to work in conjunction with the onboard pumps. Small dredging vessels typically have one slurry pump for self-suction and self-discharge. The Offshore Technology team, when selecting and configuring for dredging vessels, provides personalized slurry pump solutions based on customer needs and equipment requirements, including drive systems, hydraulic systems, and control systems.

Main Features of Slurry Pumps for Dredging Vessels

(1) Good cavitation performance, strong mud suction capacity, enabling greater excavation depth and higher concentration of extraction.

(2) Over-flow components are made of CR28 wear-resistant alloy materials with high hardness (greater than HRC60) and toughness, and they have certain corrosion resistance, ensuring a longer service life.

(3) Equipped with a complete set of auxiliary facilities for operation, including bearing lubrication systems, shaft seal water systems, sand-water separators, and electric turning gear systems.

(4) Front-mounted disassembly design, equipped with special tools, simplifying maintenance and repair processes.

Dredging vessels have a wide range of applications, with deep excavation depths and high extraction concentrations. However, they are expensive, with high usage and maintenance costs. Many dredging projects have low budgets, making it impossible to use dredging vessels for operations.

Conclusion

Different working conditions require different dredging methods, but the core equipment remains the slurry pump. Whether it is the impact of high-pressure water pumps or the stirring of agitation devices, their purpose is to better assist the slurry pump in completing dredging operations. Horizontal, vertical, and submersible slurry pumps, with their various structural forms, are widely used in dredging sites worldwide. Haichuan Pump Industry has specialized in slurry pumps for 20 years and has accumulated rich experience in dredging, sand mining, and embankment reinforcement. The company not only provides high-quality products and industry-wide solutions but also offers on-site installation services. For any questions regarding dredging and sand extraction solutions and equipment, please feel free to contact us.

TAIAN OCEAN PUMP CO.,LTD

DORIS CHEN

WHATSAPP :+86 18562293319

Email £º oc@tsbeng.com

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19