How to Choose a Sand Booster Pump Set for a Sand Mining Project?

1. What is a Sand Booster Pump Set?

A sand booster pump set is a heavy-duty pumping system designed to transport sand, slurry, and dredged materials over long distances in mining, dredging, and construction projects. It consists of:

Centrifugal sand pump (wear-resistant construction).

High-power motor or diesel engine.

Control system & piping connections.

Optional booster stations for extended pipeline transport.

These pumps are engineered to handle abrasive, high density slurries while maintaining efficiency and durability.

2. Client Request: Dredging Project Specifications

The client has a hopper dredger and needs a sand booster pump set with the following requirements:

- Flow rate: 1140 m³/h

- Sand particle size: 100 mesh (~0.15mm)

- Specific gravity: 1.625 kg/l (slurry density)

- Pipeline: 12-inch (300mm) inner diameter PE pipe

- Discharge distance: 16 km

- Required flow velocity* 4.57 m/s

Key Challenges:

Long-distance pumping (16 km) requires high pressure & multiple boosters .

Abrasive wear due to fine sand (100 mesh).

Slurry density (1.625 kg/l) affects pump power & efficiency.

3. How to Choose the Suitable Sand Booster Pump Set?

Based on the project requirements, we recommend:

Selected Pump Model: 300DS-95 Sand Booster Pump Set

| Parameter | Specification |

| Pump Type | Heavy-duty centrifugal sand pump |

| Flow Rate | 1248 m³/h (meets 1140 m³/h demand with margin) |

| Head | 97m (ensures sufficient pressure for long-distance transport) |

| Efficiency | 72% (optimized for slurry pumping) |

| Shaft Power | 457.9 kW |

| Motor | 560 kW (8-pole, 480V/60Hz) (provides extra power for wear & distance) |

| Inlet/Outlet | 300mm inlet / 250mm outlet (matches 12" pipeline) |

| Max Particle Size | 76mm (handles occasional larger debris) |

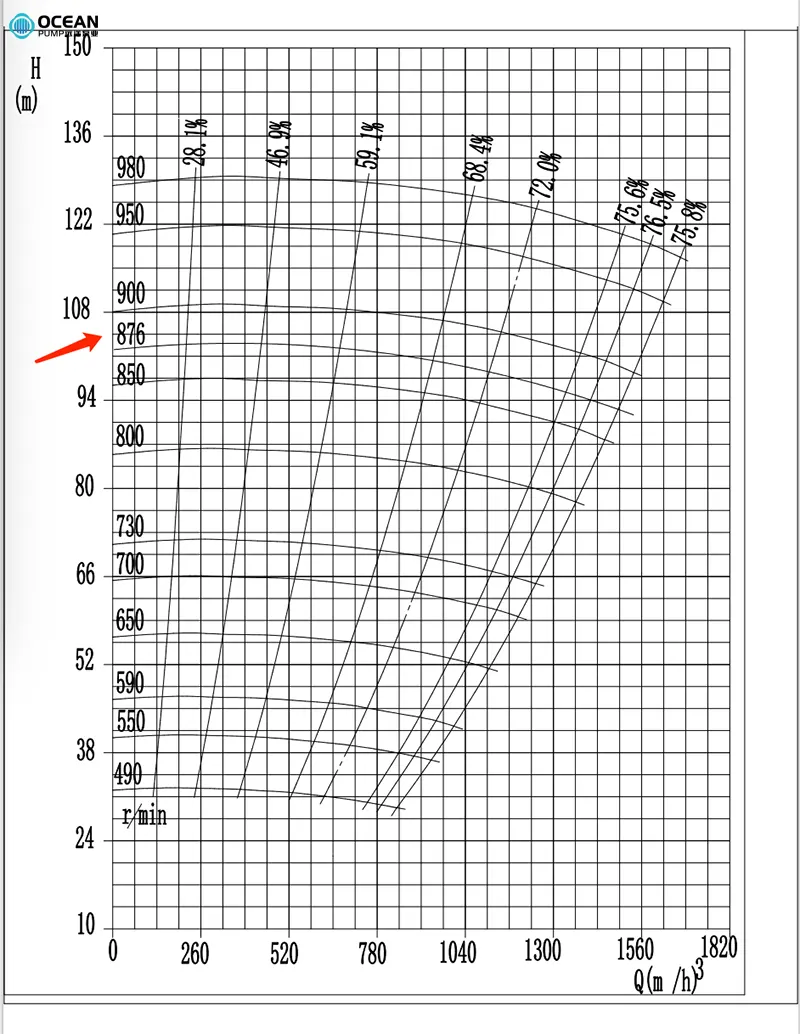

| Speed | 876 RPM (low speed reduces wear) |

Why This Pump?

Higher flow (1248 m³/h) than required (1140 m³/h) - Ensures no loss in performance over time.

97m head - Provides enough pressure for 16 km discharge (may require booster stations ).

8-pole motor (560 kW) - More torque, better for long-distance slurry pumping.

300mm inlet / 250mm outlet - Matches 12-inch PE pipe for smooth flow.

Low speed (876 RPM) - Reduces wear on impeller & casing.

4. Sand Booster Pump Performance Curves

The pump curve for the 300DS-95 model shows:

- Flow vs. Head : At 1140 m³/h, the pump delivers ~90m head (sufficient for long-distance transport).

- Efficiency Peak : ~72% at optimal flow range (1000-1300 m³/h) .

- Power Consumption : ~457.9 kW at full load.

Recommendation :

- Use multiple booster stations (every 3-5 km) to maintain pressure over 16 km .

- Install wear monitoring sensors to track impeller & casing erosion.

5. Sand Booster Pump Model Set Configuration

A complete sand booster pump set includes:

| Component | Specification |

|---------------------|------------------|

| Pump Unit | 300DS-95 Sand Pump |

| Motor | 560 kW, 8-pole, 480V/60Hz |

| Base Frame | Heavy-duty skid-mounted steel frame |

| Coupling | Flexible shaft coupling (shock absorption) |

| Control Panel | VFD (Variable Frequency Drive) for speed adjustment |

| Piping | 12-inch (300mm) PE pipe with abrasion-resistant lining |

| Sealing System | Double mechanical seals with clean water flush |

| Monitoring | Pressure & flow sensors for real-time performance tracking |

Final Recommendation:

For this hopper dredger project , the 300DS-95 sand booster pump set is the best choice due to:

High flow & head for 16 km slurry transport .

Wear-resistant materials (high-chrome alloy or rubber-lined).

Low-speed motor (876 RPM) for longer lifespan.

Scalability (can add booster stations if needed).

Would you like a detailed quotation or system layout design for this setup? Let me know how we can assist further!

TAIAN OCEAN PUMP CO.,LTD

EMAIL : oc@tsbeng.com

whatsapp :+86 18562293319

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19