What kind of pump is used for dredging?

Dredging operations typically employ specialized pumps known as dredge pumps. These pumps are specifically designed to handle the unique challenges of dredging, which involves the removal of sediment, debris, or other materials from bodies of water or the seabed.

There are different types of dredge pumps used for various dredging applications, including:

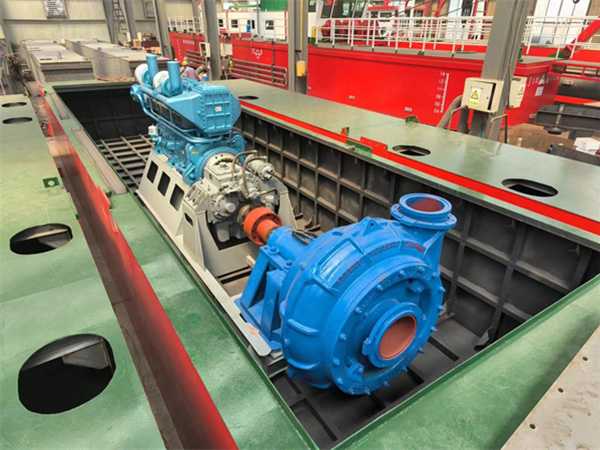

Centrifugal Pumps

Centrifugal pumps are commonly used in dredging operations. They use an impeller to create a rotating motion that imparts energy to the fluid, enabling it to be transported. These pumps are efficient and can handle a wide range of flow rates and pressures.

Gravel sand pump is designed for continuously handing the most difficult higher abrasive slurries which contain too big solids. The big particle gravel sand pump is casted as a single pump casing structure with smooth over-current channel .The overflow part is made of hard nickel and high chromium wear resistant alloy. The outlet direction of gravel pump can be adjusted according to the request direction. The gravel sand pump is suitable for delivering strong abrasive slurry containing bigger particles in mining, explosive sludge in metal melting, dredging and so on. The advantages of the pump are heavy flow, easy installation and operation, good performance of NPSH and abrasion resistance.

Submersible Pumps

Submersible pumps are designed to be fully submerged in water during operation, and they are commonly used in smaller-scale dredging projects or in situations where mobility and flexibility are important.

Submersible dredge pumps are specifically designed to handle solids, including sand, gravel, silt, and other sediment. They are equipped with impellers and volutes that are designed to handle abrasive and viscous materials commonly encountered in dredging operations.

One of the advantages of submersible dredge pumps is their ability to operate at various depths. They can be lowered to the desired depth in the water, allowing for precise dredging in specific locations. This makes them well-suited for applications such as harbor maintenance, pond and lagoon dredging, or sediment removal in shallow water bodies.

In addition to handling solids, submersible dredge pumps are often equipped with features such as agitators or cutters to aid in the loosening and breaking up of compacted materials. This enhances their efficiency in dredging operations by improving the pump's ability to handle cohesive or compacted sediments.

The submersible design of these pumps also helps to minimize noise and vibration, making them suitable for environmentally sensitive areas or urban settings.

A hydraulic submersible sand pump is a type of submersible pump that is specifically designed for handling sand, gravel, and other abrasive solids in various applications. It is commonly used in dredging, mining, construction, and other industries where the efficient removal or transfer of sand or sediment is required.

Overall, submersible dredge pumps offer versatility, maneuverability, and the capability to handle solids, making them a popular choice for smaller-scale dredging projects or applications in confined spaces.

Cutterhead Pumps

Cutterhead pumps are specialized pumps used in cutter suction dredgers. These pumps are equipped with rotating cutterheads that break up and loosen the material at the dredging site. The pump then suctions the loosened material and transports it through the pipeline. Cutterhead pumps are indeed specialized pumps used in cutter suction dredgers. These pumps are designed to handle the unique requirements of cutter suction dredging operations.

A cutter suction dredger (CSD) typically consists of a floating vessel equipped with a cutterhead, suction pipe, and discharge pipeline. The cutterhead pump is a crucial component of the dredging system.

The cutterhead is a rotating device located at the front of the suction pipe. It is equipped with a set of rotating cutting blades or teeth that break up and loosen the material at the dredging site. The cutterhead can be powered by hydraulic motors or electric motors, depending on the design of the dredger.

As the cutterhead rotates and cuts through the sediment, the loosened material is mixed with water to form a slurry. The cutterhead pump is responsible for creating suction and drawing the slurry into the suction pipe.

Inside the pump, an impeller or series of impellers generate the necessary centrifugal force to transport the slurry. The slurry is then discharged through the discharge pipeline and transported to the desired location, such as a sediment containment area or a designated disposal site.

Cutterhead pumps are specifically designed to handle the abrasive nature of the dredged material, such as sand, gravel, or clay. They are built with wear-resistant materials and components to withstand the erosive forces encountered in the dredging process.

Jet Pumps

Jet pumps, also known as eductors or ejectors, utilize the principle of fluid entrainment. They use high-velocity jets of water or a mixture of water and air to create a suction force that lifts and transports the sediment. Jet pumps are often used in shallow water or for precision dredging tasks.

The type of pump used for dredging depends on factors such as the type of material being dredged, the depth and location of the dredging site, the desired flow rate and pressure, and the specific requirements of the project.

Jet pumps, also known as eductors or ejectors, are commonly used in dredging operations, particularly in shallow water or for precision dredging tasks.

Jet pumps operate based on the principle of fluid entrainment. They use high-velocity jets of water or a mixture of water and air to create a suction force that lifts and transports sediment or other materials.

The basic design of a jet pump includes an inlet nozzle where the high-velocity jet is generated, a mixing chamber, and a discharge outlet. The high-velocity jet of water or water-air mixture is directed into the mixing chamber, creating a low-pressure zone. This low-pressure zone induces the suction and entrainment of sediment or other materials from the surrounding area.

As the sediment is entrained, it mixes with the water or water-air mixture, forming a slurry. The slurry is then transported through the discharge outlet and can be directed to a designated containment area or disposal site.

Jet pumps are often used in shallow water dredging operations where the water depth is limited. They are particularly effective in areas where traditional dredging equipment may be challenging to maneuver or operate.

Additionally, jet pumps are commonly utilized for precision dredging tasks that require controlled and localized excavation. Their ability to create a suction force in a specific area allows for targeted removal of sediment or materials without disturbing the surrounding environment.

It's important to note that jet pumps may have limitations in terms of the volume of material they can handle compared to other types of dredging pumps. They are most suitable for smaller-scale dredging operations or situations where precise and localized dredging is required.

Overall, jet pumps are a valuable tool in dredging operations, especially in shallow water or for precision dredging tasks, offering flexibility, control, and the ability to create suction forces for lifting and transporting sediment or other materials.

It's important to note that dredging operations often involve a combination of pumps, pipelines, and other equipment to effectively remove and transport sediment or other materials. The selection of the appropriate pump(s) is typically based on the specific needs and conditions of the dredging project.

If you want to dredge sand slurry ,you can contact

Taian Ocean Pump Co.,ltd

Whatsapp : +86 18562293319

Email : oceanpump12@tsbeng.com

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19