A Detailed Analysis of Core Differences Between Slurry Pumps and Mud Pumps

In the field of industrial fluid transfer, slurry pump and mud pumps are often conflated due to their shared function of conveying solid-laden slurries. This confusion is further compounded by ambiguous English translations-for instance, "slurry pump" is frequently mistranslated as "mud pump" incorrectly. While their applications may overlap to some extent, the two pump types differ drastically in terms of definition scope, core use cases, structural design, and performance characteristics. Below is a comprehensive comparison across multiple dimensions.

I. Core Definitions & Scopes: Distinct Essential Attributes

Definitions serve as the foundation for distinguishing these two pumps, with clear disparities in their scope boundaries and core focuses-particularly regarding the "specificity of application scenarios."

| Comparison Dimension | Mud Pump | Slurry Pump |

| Core Definition | In a narrow sense, it specifically refers to a specialized pump for the oil drilling industry and acts as a critical component of drilling equipment. Broadly, it may sometimes encompass other non-clear-water pumps, but the industry generally recognizes its core purpose as "supporting drilling operations." | A type of centrifugal pump defined by the "medium it conveys." It boosts the kinetic and potential energy of solid-liquid mixtures using centrifugal force generated by impeller rotation, serving as a versatile slurry transfer device. |

| Scope Boundary | Its scope is narrow, with core application limited to "drilling fluid conveyance." In other scenarios (e.g., sewage or low-concentration slurry transfer), the term "mud pump" is often a colloquial misnomer-these pumps typically belong to other categories. | Its scope is broad, covering industries such as mining, electric power, dredging, and chemical engineering. In practice, pumps like sand pumps, dredge pumps, desilting pumps, and impurity pumps are often classified as sub-types of slurry pumps. |

| Corresponding English | The standard term is Mud Pump, which is tightly associated with "drilling mud" and must not be confused with "Slurry Pump." | The standard term is Slurry Pump. "Slurry" specifically denotes "high-concentration solid-liquid mixtures," directly aligning with the pump's functional purpose. |

II. Core Applications & Industrial Scenarios: Non-Overlapping Use Cases

The most intuitive difference between the two lies in their applications-each is tailored to "dedicated scenarios" with almost no overlap.

1. Mud Pump: Exclusively for "Oil Drilling"

The core function of a mud pump is to deliver drilling fluids (e.g., mud or water) to drill holes, making it the "lifeline" of drilling operations. Its key roles include:

- Cooling the drill bit: Removing heat generated by the bit's high-speed rotation via drilling fluids to extend the bit's service life.

- Transporting cuttings: Carrying rock fragments produced during drilling back to the surface with the fluid to prevent hole blockages.

- Protecting the wellbore: Using the mud's viscosity to form a "mud cake" on the wellbore wall, preventing collapse.

Mud pumps are used solely in the oil and natural gas drilling industry with no applications in other sectors. The "mud" they convey must meet the criteria of "high viscosity ( < 10000Pa.s) and containing cuttings"-a requirement distinct from slurry needs in other industries.

2. Slurry Pump: A "Versatile Slurry Transfer Tool" for Multiple Industries

The core function of a slurry pump is to convey high-concentration slurries with abrasive solid particles. Its applications span multiple heavy industries, and it may be referred to by different names in specific scenarios (though it remains a slurry pump in essence):

- Mining industry (80% of applications): Transferring mineral slurries (e.g., copper or iron ore slurries) in mineral processing plants. Particularly in the "primary ore separation" stage-where slurries are highly abrasive and contain coarse particles-specialized wear-resistant designs are required.

- Electric power industry: Used for "hydraulic ash removal" in thermal power plants. It transports "ash-slag slurry" (formed by mixing water with coal combustion residues) to storage sites, and is sometimes called an "ash-slag pump" in this context.

- Dredging/desilting industry: For river desilting and marine sand extraction, conveying slurries with sand and silt. It is often termed a "dredge pump" or "sand pump" here.

- Chemical/coal washing industry: In the chemical sector, it conveys corrosive slurries with crystals; in coal washing plants, it transports coal slurries containing lumps and gangue (requiring anti-clogging designs).

III. Performance Characteristics: Customized Traits for Target Scenarios

The performance parameters of both pumps are engineered around their "core use cases," with significant differences in key metrics (e.g., pressure, flow rate, and self-priming capability).

| Performance Indicator | Mud Pump | Slurry Pump |

| Discharge Pressure | Independent of rotational speed, maintaining high pressure even at low flow rates (to meet the demand for "high-pressure fluid delivery in deep drill holes"). | Pressure depends on rotational speed and impeller design, requiring adjustment based on transfer distance and slurry concentration. Most models operate at "medium-low pressure with high flow rates" (suitable for long-distance transfer). |

| Flow Rate Regulation | Flow rate is proportional to rotational speed, allowing precise adjustment via variable-speed mechanisms or motors (to adapt to drilling fluid needs at different drilling stages). | It offers a wide flow rate range; multi-stage series connection can enhance transfer capacity, making it suitable for high-flow scenarios (e.g., mineral slurry or ash-slag transfer). |

| Self-Priming Capacity | Boasts strong self-priming capability, enabling direct fluid suction without a foot valve (simplifying pipeline installation at drilling sites). | Has weak self-priming capability; in most cases, it requires a "priming device" or "low-level installation," relying on pipeline liquid level differences to assist fluid intake. |

| Slurry Adaptability | Suitable for high-viscosity, high-concentration slurries ( < 10000Pa.s), with no slurry agitation or shearing (to avoid compromising the mud's "wellbore protection" function). | Suitable for highly abrasive, coarse-particle slurries (e.g., ore, slag). Flow-passage components must use "high-chromium alloy or wear-resistant rubber" to extend service life. |

| Operational Stability | Operates stably with low vibration and noise (drilling requires long-term continuous operation, demanding high stability). | Due to the coarse, abrasive nature of the conveyed slurry, it experiences relatively high vibration during operation. Stability is optimized via "bearing reinforcement and impeller balancing designs." |

IV. Structural Design: Differences from "Wearing Parts" to "Overall Architecture"

Structural design is fully aligned with "performance requirements," and the two pumps differ significantly in casing type, flow-passage components, and transmission methods-especially in their focus on "wear resistance and anti-clogging."

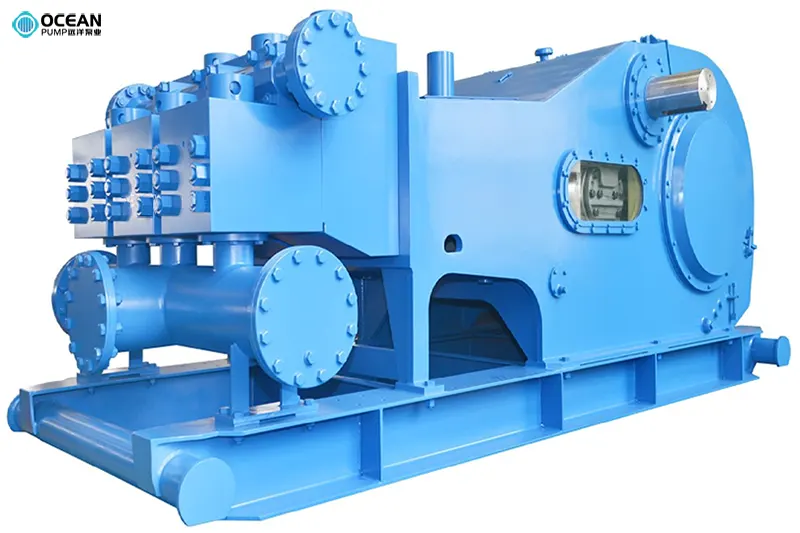

1. Slurry Pump: Focused on "Wear Resistance & Multi-Scenario Adaptability"

Since slurry pumps handle highly abrasive media, their design prioritizes "extending the service life of flow-passage components" and "flexibility across scenarios." Key structural features include:

- Casing Type:

- The mainstream double-casing structure (e.g., M, AH, HP models): The outer "pressure-bearing casing" (made of gray cast iron or ductile iron for pressure resistance) encloses an inner "replaceable wear-resistant lining" (high-chromium alloy or wear-resistant rubber). When the lining is worn through, only the lining needs replacement-reducing maintenance costs.

- Single-casing structures (e.g., D, G, SP models) for specific scenarios: The pump body and impeller are directly crafted from wear-resistant metal, suitable for low-abrasion slurries (e.g., concentrate transfer).

- The outlet can be installed at "8 different angles" to adapt to on-site pipeline layouts.

- Flow-Passage Components: Impellers, throat bushes, and wear plates are all made of "high-chromium alloy (Cr27, Cr30)" or "wear-resistant rubber." Impellers feature "back blades" (front and rear) to reduce slurry leakage and protect the impeller itself.

- Shaft Sealing: Supports "packing seals, auxiliary impeller seals, and mechanical seals" to meet sealing needs for different slurries (e.g., mechanical seals for corrosive media).

- Transmission Methods: Diverse and flexible, including V-belt drive, elastic coupling drive, and variable-frequency drive. Adjustments can be made based on speed requirements (e.g., variable-frequency control in coal washing plants to regulate flow and prevent clogging).

2. Mud Pump: Focused on "High Pressure & Stable Fluid Delivery"

As mud pumps target "high-pressure drilling scenarios," their design emphasizes "high-pressure sealing" and "easy replacement of wearing parts." Key structural features include:

- Core Components: Mainstream models adopt a "piston/plunger design" (replacing centrifugal pump impellers). High-pressure fluid delivery is achieved via the reciprocating motion of the "crankshaft-crosshead-piston" (to meet deep-hole drilling demands).

- Concentrated Wearing Parts: Critical wear components (cylinder liners, cups, suction/discharge valves, crosshead sliding sleeves) feature "quick-disassembly structures" (frequent replacement is needed at drilling sites to minimize downtime).

- High Sealing Requirements: Sealing between the cylinder block and piston relies on "rubber cups," which must withstand high pressure and prevent mud leakage (to avoid disrupting drilling pressure).

- Compact Overall Structure: Mostly integrated with drilling equipment, it has a small footprint-ideal for the limited space of drilling platforms.

V. Summary: Key Differences at a Glance

| Comparison Dimension | Mud Pump | Slurry Pump |

| Core Scenarios | Oil drilling (drilling fluid conveyance) | Mining, electric power, dredging, chemical engineering (abrasive slurry transfer) |

| Medium Adaptability | High-viscosity ( < 10000Pa.s), high-concentration mud with cuttings | Highly abrasive, coarse-particle slurries (ore, slag, sand, etc.) |

| Core Performance | High pressure, strong self-priming, no slurry shearing | High flow rate, wear resistance, multi-scenario adaptability |

| Structural Core | Piston/plunger reciprocating structure; quick-wear part replacement | Double-casing (wear-resistant lining), centrifugal impeller, multiple transmission options |

| Industry-Specific Names | None (drilling-only use) | Sand pump, dredge pump, ash-slag pump, impurity pump (scenario-specific aliases) |

The above comparison makes it clear that mud pumps are "drilling-specialized equipment," while slurry pumps are "versatile slurry transfer tools for multiple industries". Their differences stem from the "fundamental needs of their target scenarios," and they must not be confused in practice. For pump selection, it is essential to first clarify the conveyed medium (viscosity, abrasiveness, particle size) and industry context, then match it to the appropriate pump type.

Tai'an OCEAN Pump (OCEAN Pump) Co., Ltd. being a leading sand pump and sand dredger solutions manufacturer, supplier, and exporter in China. With a team of over 30 talented sand pump experts and a 15,000 square meters factory, it seems like you have the resources to meet the demands of your customers.

We offer a wide range of products, including more than 4 series and 20 kinds of sand pumps, slurry pump, sand dredgers, and related parts. This variety allows you to cater to different pumping requirements and provide comprehensive solutions to clients.

Any inquiry£¬welcome contact

TAIAN OCEAN PUMP CO.,LTD

WHATSAPP:+86 18562293319

Email:oc@tsbeng.com

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19