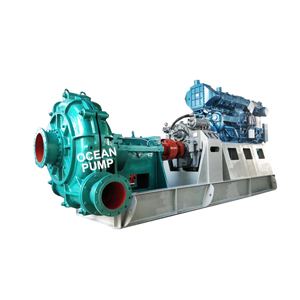

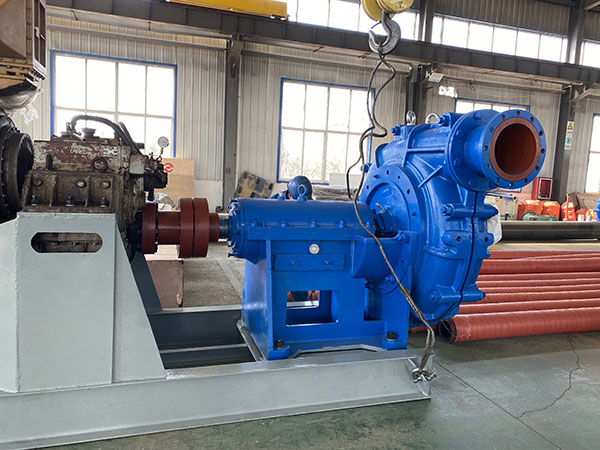

High concentration centrifugal mine slurry pump

- Description

High concentration centrifugal mine slurry pump is horizontal, single stage and double casing pump. The mine slurry pump is innovative in the design of structure and hydraulic performance. Over-Flow components are made of abrasion resistant high chromium alloy, it has the characteristics of high efficiency, energy saving, wear-resisting and reliable running etc.

The centrifugal mine slurry pump can convey gravel, slurry or sand with the solid and liquid density up to 60%. The high concentration slurry pump is suitable to convey strong erosion slurry, slag or grout contained solid particles. The mine slurry pump is widely used in pumping sand, land reclamation, electric coal-ash and tailing in metallurgy industry, etc.

1. The mine slurry pump has the excellent water performance, high efficient and low wear rate with the help of CAD design and CAE simulation.

2. Smooth flow channel, good anti-blocking performance, excellent cavitation performance.

3. Vice impeller seal, packing seal or the mechanical seal to ensure no slurry leakage. Reliable design can ensure the pump work with long time.

4. Adopt the thin oil lubrication metric bearings with reasonable set of lubrication. Cooling system to ensure that the bearings run at low temperature.

5. With special treatment, the centrifugal mine slurry pump can be used the corrosion working conditions like seawater ash ,seawater and salt spray.

6. Within the allowable pressure range, the pump can be used in multiple stages series connection .with allows maximum working pressure for 3.6Mpa.

High head Slurry Pump

Diesel Driven Slurry Transfer Pump

The mine slurry pump can be classified into rubber lining slurry pump and metal lining (high chromium alloy) slurry pump according to the lining material.

There are big difference between the rubber lining and metal lining slurry pump. Rubber lining slurry pump is more corrosion resistance than the high chromium lining slurry pump , but the abrasion resistance is not very good. While the metal high chrome alloy lining has generally good wear resistance.

So how to choose your slurry pump is based on the customer’s industrial and mining conditions and the composition of the slurry. Generally speaking, rubber lining slurry pump is suitable for the not very strong abrasive slurry like nickel, molybdenum and other minerals, metal lining slurry pump is suitable for iron ore, gold and other relatively strong abrasive slurry.

AHR type rubber lined slurry pump is cantilever, horizontal and double shell axial suction centrifugal slurry pump. The outlet of the pump can be installed according to the need of 45 ? interval, rotating eight different angle lining slurry pump structure installation. this mine slurry pump is equipped with a replaceable rubber lining, the over-flow parts are wear-resistant anti-corrosion natural rubber. It can be used for conveying slurry with small particle , no sharp corners particles and high concentrations and corrosive slurry.

Seal form: packing seal, vice impeller seal, packing plus impeller seal, mechanical seal and other types.

Rubber lining slurry pump drive type: DC direct drive, CR parallel belt drive, ZVZ upper and lower belt drive, CV vertical belt drive and other types.

Model meaning: For example: DS150-100 (DS: multi-purpose sediment pump; 150: inlet diameter; 100: impeller diameter)

| No. | Shaft power (Kw) | Clear water performance | Weight

(kg) | ||||

| Flow

(I/s) |

Head

(m) |

Speed

(r/min) |

Eff.

?% |

NPSH

(m) | |||

| DS350-100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 81.1 | 3 | 5265 |

| DS350-95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 78.1 | 3 | 5220 |

| DS350-90 | 560 | 505-1844 | 21.2-79.9 | 400-730 | 82.8 | 3.9 | 5005 |

| DS350-85 | 450 | 477-1742 | 18.9-71.3 | 400-730 | 79.8 | 3.8 | 4965 |

| DS350-70 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 3560 |

| DS350-65 | 500 | 589-2166 | 13.8-66.2 | 490-980 | 77.4 | 3.7 | 3531 |

| DS350-56 | 250 | 395-1568 | 9.7-46.0 | 490-980 | 80.9 | 3.5 | 3030 |

| DS300-103 | 560 | 402-1573 | 29.7-110.5 | 400-730 | 74.5 | 2.8 | 5085 |

| DS300-96 | 560 | 403-1466 | 25.4-93.7 | 400-730 | 77.8 | 3.5 | 5035 |

| DS300-90 | 450 | 378-1374 | 22.3-82.4 | 400-730 | 73.8 | 3.4 | 4980 |

| DS300-85 | 800 | 376-1504 | 30.1-128.7 | 490-980 | 76.5 | 3.5 | 4530 |

| DS300-83 | 800 | 367-1469 | 28.7-122.7 | 490-980 | 75.5 | 3.5 | 4514 |

| DS300-80 | 710 | 354-1416 | 26.7-114.0 | 490-980 | 73.5 | 3.4 | 4490 |

| DS300-78 | 630 | 415-1796 | 21.1-102.5 | 490-980 | 71.5 | 3.2 | 4474 |

| DS300-75 | 560 | 300-1480 | 20.8-97.5 | 490-980 | 77.5 | 3 | 3480 |

| DS300-73 | 500 | 292-1441 | 19.7-92.4 | 490-980 | 76.5 | 3 | 3466 |

| DS300-70 | 450 | 280-1381 | 18.1-84.9 | 490-980 | 74.5 | 2.9 | 3446 |

| DS300-68 | 450 | 272-1342 | 17.1-80.1 | 490-980 | 73.5 | 2.7 | 3432 |

| DS300-65 | 315 | 299-1249 | 15.4-71.0 | 490-980 | 76.5 | 3 | 3020 |

| DS300-63 | 315 | 290-1211 | 14.4-66.7 | 490-980 | 75.9 | 3 | 3008 |

| DS300-60 | 280 | 276-1153 | 13.1-60.5 | 490-980 | 73.9 | 2.8 | 2991 |

| DS250-85 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 4110 |

| DS250-75 | 355 | 225-900 | 22.8-102.9 | 490-980 | 74.4 | 3 | 3070 |

| DS250-73 | 355 | 219-876 | 21.6-97.5 | 490-980 | 73.1 | 3 | 3056 |

| DS250-70 | 315 | 205-976 | 19.4-86.4 | 490-980 | 75.6 | 2.8 | 2465 |

| DS250-68 | 315 | 199-948 | 18.3-81.5 | 490-980 | 74.6 | 2.8 | 2453 |

| DS250-65 | 250 | 235-950 | 16.4-72 | 490-980 | 79.6 | 2.5 | 2323 |

| DS250-63 | 250 | 228-921 | 15.4-67.6 | 490-980 | 78.6 | 2.5 | 2311 |

| DS250-60 | 185 | 218-870 | 13.9-62 | 490-980 | 83.5 | 2.5 | 2223 |

| DS250-58 | 185 | 211-841 | 13-57.9 | 490-980 | 82.5 | 2.5 | 2214 |

| DS200-70 | 185 | 93-401 | 20-91.2 | 490-980 | 62.3 | 2 | 2245 |

| DS200-65 | 200 | 150-600 | 17.4-75.7 | 490-980 | 70.8 | 2.5 | 2223 |

| DS200-63 | 185 | 146-582 | 16.3-71.1 | 490-980 | 69.8 | 2.5 | 2211 |

| DS200-60 | 160 | 135-550 | 14.7-63.5 | 490-980 | 75.9 | 2.5 | 2203 |

| DS200-58 | 132 | 131-532 | 13.7-59.3 | 490-980 | 74.9 | 2.5 | 2033 |

| DS200-55 | 110 | 124-504 | 12.3-53.4 | 490-980 | 72.9 | 2.3 | 2019 |

| DS200-58 | 160 | 134-596 | 12.8-61 | 490-980 | 69.1 | 2 | 2063 |

| DS200-57 | 110 | 95-427 | 13.2-56.3 | 490-980 | 67.8 | 1.8 | 2023 |

| DS200-50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 76.8 | 2.5 | 1735 |

| DS200-48 | 75 | 111-442 | 8.7-39.7 | 490-980 | 75.8 | 2.5 | 1728 |

| DS200-42 | 132 | 142-550 | 12.1-62.8 | 700-1480 | 77.1 | 2.2 | 1605 |

| DS150-50 | 160 | 85-360 | 20.5-100.2 | 700-1480 | 69.6 | 2.5 | 1475 |

| DS150-46 | 132 | 79-331 | 17.3-84.8 | 700-1480 | 67.6 | 2.3 | 1461 |

| DS150-42 | 90 | 66-275 | 14.7-70.8 | 700-1480 | 71 | 2.5 | 1075 |

| DS150-39 | 75 | 61-255 | 12.6-61 | 700-1480 | 69 | 2.4 | 1064 |

| DS150-42 | 90 | 83-365 | 12.7-66.8 | 700-1480 | 71.6 | 2.5 | 1085 |

| DS150-36 | 55 | 61-245 | 9.7-49.5 | 700-1480 | 71.6 | 2 | 1010 |

| DS150-33 | 45 | 56-225 | 8.2-41.6 | 700-1480 | 69.6 | 1.8 | 1003 |

| DS125-52 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 1465 |

| DS125-42 | 75 | 61-204 | 14.4-70.4 | 700-1480 | 66.7 | 2.5 | 1053 |

| DS125-39 | 55 | 57-189 | 12.4-60.7 | 700-1480 | 64.7 | 2.4 | 1042 |

| DS125-36 | 45 | 46-190 | 9.6-51.4 | 700-1480 | 67.7 | 2.5 | 980 |

| DS125-33 | 37 | 43-174 | 8-43.2 | 700-1480 | 65.7 | 2.3 | 973 |

| DS100-30 | 15 | 23-79 | 7.4-34.8 | 700-1480 | 63.5 | 2 | 504 |

| DS100-27 | 11 | 20-71 | 6-28.2 | 700-1480 | 61.5 | 1.8 | 500 |

| DS80-50 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3 | 1378 |

| DS80-46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 1082 |

| DS80-33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 42.1 | 2.9 | 537 |

| DS50-19 | 7.5 | 4-23 | 9-44.6 | 700-1480 | 52.4 | 2.5 | 121 |

More Technical parameters of mine slurry pump,please click here to download

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19