Influence Mechanism and Optimization Strategies of Self-performance of Slurry Pumps on Transportation Distance

The transportation distance of slurry pumps is affected by multiple factors, including self-performance, medium characteristics, pipeline system design, operating conditions, and external environment. This paper focuses on analyzing the influence mechanism of the pump's self-performance on transportation distance and proposes corresponding optimization strategies.

I.Influence Mechanism of Impurity Pump Self-performance on Transportation Distance

1. Relationship Between Head-Flow Characteristics and Transportation Distance

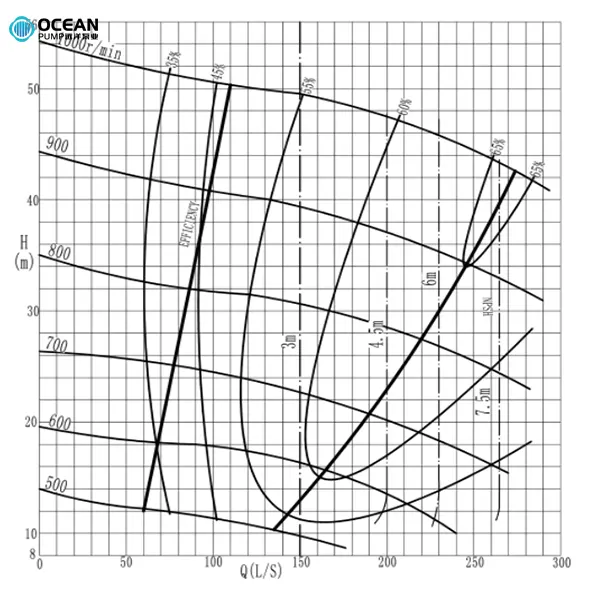

Head (H), as a core parameter for pumps to overcome pipeline resistance, its relationship curve with flow (Q) (H-Q curve) determines the applicable working conditions of the pump.

- Low-head pumps: Suitable for short-distance and low-resistance transportation. However, during long-distance transportation, insufficient head may easily cause a sharp drop in flow.

- High-head pumps: Capable of providing greater pressure, but excessive selection may lead to efficiency decline and increased energy consumption.

Estimation formula for critical transportation distance (simplified based on Bernoulli equation):

(Lmax)

\[ L_{max} = \frac{H \cdot \rho g}{\lambda \cdot \frac{v^2}{2D} + \Delta Z} \]

Where:

- H: Available head of the pump(m)

- L: Pipeline friction coefficient

- v: Flow velocity(m/s)

- D: Pipe diameter(m)

- Z: Elevation difference (m)

Optimization strategies:

- Select pump types with gentle H-Q curves to better adapt to flow fluctuations (see attached curve diagram below).

- Adopt variable frequency regulation technology to ensure the pump always operates in the high-efficiency zone.

2. Influence of Impeller Design on Transportation Capacity

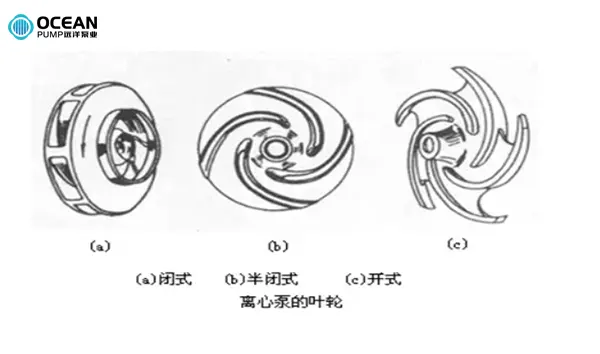

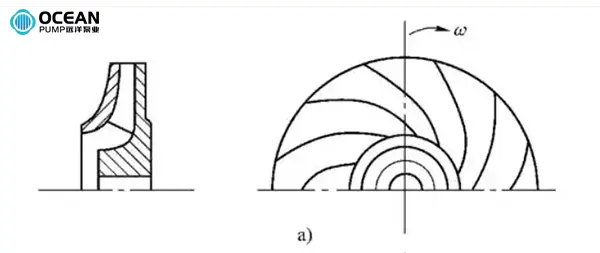

As the core component of impurity pumps, the impeller's structure directly affects particle passability and head efficiency.

|Impeller Type|Application Scenario|Impact on Transportation Distance|

|Open impeller|Large particles, high concentration|Good passability but low efficiency (shortens economic transportation distance)|

|Closed impeller|Small particles, high head requirements|High efficiency but prone to clogging (requires higher maintenance costs)|

|Semi-open impeller|Medium particles|Balances passability and efficiency|

CFD simulations have found:

- Increasing the number of impeller blades can improve head but exacerbate particle collision and wear.

- Backward-curved blade design can reduce turbulence and enhance the stability of long-distance transportation.

Optimization directions:

- Use wear-resistant alloy impellers (such as Cr28 high-chromium cast iron) to extend service life. Cr28 material contains 28% chromium (Cr), giving it excellent wear and corrosion resistance. Additionally, it contains appropriate amounts of carbon (C), silicon (Si), manganese (Mn), and other trace elements, which collectively make Cr28 material perform well in hardness, toughness, and high-temperature stability. The hard phase in high-chromium cast iron is mainly M7C3 carbides, which have extremely high hardness (HV1500-1800), thus maintaining integrity for a long time under wear.

- Optimize blade angles to reduce the risk of solid-phase deposition, including:

- Optimizing the leading edge profile of blades;

- Adjusting blade bending methods;

- Using twisted blades;

- Optimizing impeller inlet design;

- Optimizing impeller outlet blade height.

3. Constraints of Power and Efficiency

The efficiency (¦Ç) of impurity pumps directly affects transportation economy. Low-efficiency pumps can cause:

- Increased energy consumption and operating costs for the same transportation distance.

- Risk of motor overload, limiting maximum transportation capacity.

Influence factors of efficiency:

- Mechanical loss: Mainly from bearing and seal friction (5%-10%).

- Hydraulic loss: Caused by turbulence in the impeller and volute (15%-25%).

- Volumetric loss: Caused by internal leakage (3%-8%).

Experimental data comparison (OCEAN Pump Industry 300GN-50 type pump):

|Working Condition|Efficiency|Maximum Transportation Distance (km)|

|New pump (optimized impeller)|78%|3.2|

|Worn pump|62%|2.1|

Optimization measures

- Regularly monitor efficiency and replace worn components in a timely manner.

- Adopt high-efficiency hydraulic models, such as low-specific-speed design.

II.Optimization Strategies and Engineering Applications

1. Pump Type Matching and System Integration

- For long-distance transportation, prioritize multi-stage pumps or series pump sets to achieve step-by-step pressure increase.

- For high-concentration media transportation, use a combination of large-channel impellers and high-power motors.

2. Intelligent Control Technology

- Variable Frequency Drive (VFD): Dynamically adjusts rotational speed to adapt to resistance changes in different trasportation stages.

- Internet of Things (IoT) monitoring: Real-time analysis of head and flow data to predict critical transportation distances.

Engineering case: During the large-scale construction of Hangzhou Asian Games venues in 2019, a large amount of construction sediment could not be stacked in Hangzhou and needed to be transported to the Shangyu in Shaoxing, Zhejiang. The construction team laid pipelines along the river and used slurry pumps in series for transportation, with the farthest transportation distance reaching 60 km. At that time, YuanYang Pump Industry's 450PNS-35 type pump with a 450 kW motor was selected, with each pump transporting 3 km and a total of 20 pumps used in series. By applying variable frequency control technology, pressure sensors were used to detect head and flow data and automatically adjust the rotational speed, with a PLC system realizing all operations, successfully completing the project.

3. Gearbox Configuration

If driven by a diesel engine, a gearbox with a suitable gear ratio is required.

4. Case Study

Problem: A pump experienced insufficient transportation distance after a period of use.

**Cause**: Impeller wear led to a 30% efficiency decline and head attenuation.

**Solution**: Replaced with a wear-resistant impeller and adopted variable frequency control, restoring the transportation distance to the design parameter.

Nanjing tunnel transportation project**: Using YuanYang Pump Industry's 350GN-50 pump type, the original designed transportation distance was 4 km. After operating for two months, the actual transportation distance was only 2.8 km under satisfied flow conditions. After replacing the impeller and front guard plate, the transportation distance was increased to 4 km.

III.Conclusions

1. The transportation distance of impurity pumps is mainly determined by self-performance factors such as head, impeller design, and efficiency.

2. Optimizing impeller structure and matching high-efficiency working conditions can significantly improve economic transportation distance.

3. Future trend: Integrating CFD simulation and intelligent control technology to achieve adaptive long-distance transportation.

Prospect* Further research on new technologies such as nano-coated impellers, magnetic levitation bearings, and more wear-resistant materials to reduce energy consumption and extend pump service life.

more details pls contact:

TAIAN OCEAN PUMP CO.,ltd

whatsapp:+86 18562293319

EMAIL : oc@tsbeng.com

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19