Everything You Need to Know About Big Flow Double Suction Pump

The world of industrial pumping systems relies on efficiency, reliability, and performance to ensure smooth operations. When it comes to handling large volumes of fluid, one standout pump has revolutionized the industry: the big flow double suction pump. With its exceptional capabilities and ability to handle substantial flow rates, this powerful and versatile device has become an indispensable tool in numerous sectors.

From water supply and treatment to irrigation, HVAC systems, power generation, and beyond, understanding the big flow double suction pump is crucial for those involved in industries that require the movement of significant fluid volumes. In this article, we will delve into the intricacies of this remarkable pump, explaining its working principles, advantages, applications, and more.

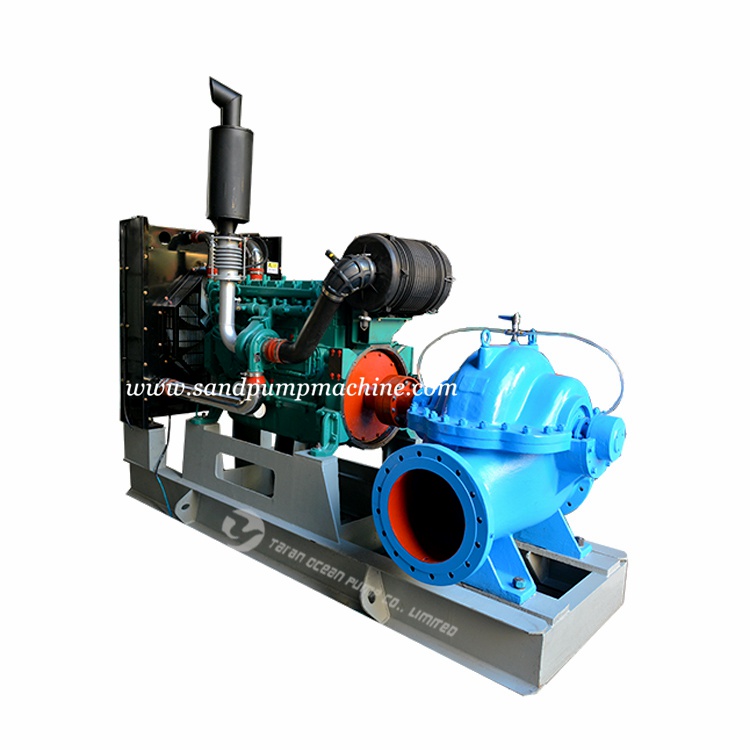

The big flow double suction pump, proudly manufactured by Tai’an Ocean Pump, combines cutting-edge technology, innovative design, and exceptional performance. With its ability to handle substantial flow rates, this pump has become a game-changer in fields such as water supply and treatment, mining, dredging, and more.

Tai’an Ocean Pump’s big flow double suction pump stands out for its exceptional efficiency, reliability, and power. By harnessing the principles of hydraulic engineering, this pump optimizes fluid handling processes, ensuring smooth and efficient operations. We will uncover the advantages it offers, including enhanced performance, reduced downtime, and energy efficiency, all of which contribute to improved productivity and cost-effectiveness.

What is Big Flow Double Suction Pump?

The big flow double suction pump is a type of centrifugal pump specifically designed to handle large volumes of fluid efficiently. As the name suggests, it is characterized by its ability to intake fluid from both sides of the impeller, ensuring balanced hydraulic forces and minimizing axial thrust.

This pump is widely recognized for its high flow rate capabilities, making it an ideal choice for applications that require the movement of substantial amounts of fluid. It is commonly used in industries such as water supply and treatment, irrigation, power generation, HVAC systems, mining, and more.

The design of the big flow double suction pump features a casing with two suction inlets on opposite sides, allowing fluid to enter from both directions. This unique design enables the pump to achieve high efficiency, smooth operation, and reduced vibration.

How Big Flow Double Suction Pump Works

The big flow double suction pump operates on the principles of centrifugal force and fluid dynamics to efficiently move large volumes of fluid. Let’s explore how it works:

Impeller Design: The pump consists of a central impeller that rotates within a casing. The impeller blades are curved and designed to create a centrifugal force when rotating. The impeller is precisely balanced to minimize vibration and ensure smooth operation.

Double Suction Inlets: One of the key features of the big flow double suction pump is its double suction inlets. These inlets are positioned on opposite sides of the impeller, allowing fluid to enter from both directions simultaneously. This design ensures a balanced flow and minimizes axial thrust, resulting in stable operation and reduced wear on the pump components.

Fluid Intake: As the impeller rotates, the fluid enters the pump through the two suction inlets. The rotating impeller blades impart kinetic energy to the fluid, causing it to move outward due to centrifugal force.

Conversion of Kinetic Energy to Pressure Energy: As the fluid moves outward, it encounters the stationary casing of the pump. The shape of the casing is designed to gradually increase in diameter, which converts the kinetic energy of the fluid into pressure energy. This process is known as diffusion or volute action.

Discharge: The fluid, now under increased pressure, exits the pump through a single outlet located at the center of the casing. From there, it can be directed to the desired destination through a network of pipes or channels.

Efficiency and Performance: The big flow double suction pump is renowned for its high hydraulic efficiency, which is achieved through careful design and engineering. The impeller, casing, and other components are optimized for smooth fluid flow, minimal energy losses, and reduced turbulence, ensuring maximum performance and minimal power consumption.

By utilizing the principles of centrifugal force, balanced flow, and efficient fluid dynamics, the big flow double suction pump is capable of handling large volumes of fluid with excellent efficiency and reliability. Its unique design and operational characteristics make it a preferred choice for applications that demand high flow rates and optimal fluid handling capabilities.

Advantages of Big Flow Double Suction Pump

Efficient High-Speed Fluid Transfer in a Compact Form:

These pumps excel in high-speed water transfer scenarios, offering uniform performance in a streamlined, compact design. Unlike single suction pumps that require larger dimensions and impeller diameters, the double suction counterparts provide enhanced rotational speed, volumetric efficiency, and reduced size and weight.

Extended Bearing Lifespan:

Designed for longevity, these pumps feature continual grease lubrication for their bearings throughout their operational lifespan. This robust structure ensures extended bearing life and enables straightforward inspection, repair, or replacement when necessary.

Elevated Impeller Efficiency:

The symmetrical double-suction design minimizes axial forces on the impeller, resulting in superior fluid flow compared to single-suction pumps. However, this innovation requires careful consideration of potential wear due to axial thrust during fluid entry. Resourceful impeller designs, including the incorporation of wear rings, address this complexity.

Optimized Pump Efficiency and Acoustic Performance:

These pumps prioritize silent efficiency, maintaining high performance even in the presence of wear on rings and bearings. The ability to replace and inspect components ensures sustained efficiency. The pump’s smooth inner surfaces contribute to its efficiency agenda while minimizing acoustic disturbances.

Ingenious Chamber Blueprint:

The chamber design showcases ingenuity with its co-axial inlet and outlet configuration. The minimal bearing separation and concise shaft design offer operational benefits, complemented by fluid-tight seals that prevent leakage. The pumps also provide the flexibility of rotation direction without requiring part replacement. For applications requiring elevated head pumping, the option of a double volute chamber ensures optimal fluid transfer.

Seamless Maintenance and Durability:

These pumps are shielded against corrosive influences, as the pump shaft avoids direct fluid contact, enhancing its longevity. They generate minimal vibration during operation, contributing to a serene environment. Replaceable bushings on the shaft further facilitate maintenance. The pump components, thoughtfully designed to minimize direct fluid interaction, ensure durability.

Embracing these pumps brings forth efficient high-speed fluid transfer in a compact form, extended bearing lifespan, elevated impeller efficiency, optimized pump efficiency and acoustic performance, an ingenious chamber blueprint, and seamless maintenance and durability. These advantages position these pumps as reliable and efficient solutions for various fluid handling applications.

Applications of Big Flow Double Suction Pump

The versatility of the big flow double suction pump extends across various industries. While single-suction pumps have their place in activities like agricultural water pumping, the double-suction pumps fill the gap in industries that require more than what single-suction counterparts can offer. Sectors such as mining, power generation, municipal water supply, and a wide range of domains benefit from the capabilities of double-suction pumps. These pumps find utility in the following applications:

Water supply pumping stations

Industrial water supply systems

Sewage systems and petrochemical industries

Cooling water supply

Factory water supply

Industrial water treatment systems

Firefighting applications

Marine systems

Refinery general services

Agriculture and irrigation

Drainage systems

The big flow double suction pump’s adaptability makes it a valuable asset in numerous industries and applications, catering to diverse fluid handling needs effectively.

Key Considerations for Selecting a Big Flow Double Suction Pump

When selecting a big flow double suction pump, several key considerations should guide your decision-making process. Here are some important factors to keep in mind:

Flow Rate Requirements: Determine the desired flow rate for your application. Big flow double suction pumps are specifically designed to handle large volumes of fluid efficiently. Ensure that the pump’s flow rate matches or exceeds your requirements to ensure optimal performance.

Head Pressure: Consider the required head pressure or the vertical distance the pump needs to lift the fluid. This factor is crucial for determining the pump’s power and efficiency. Select a pump that can handle the required head pressure effectively.

Fluid Compatibility: Assess the compatibility of the pump materials with the fluid being pumped. Different fluids may require specific materials to avoid corrosion or damage. Ensure that the pump is constructed with materials suitable for the fluids it will handle.

Efficiency: Evaluate the pump’s hydraulic efficiency, which indicates how effectively it converts input power into fluid flow. Higher efficiency results in lower operating costs and reduced energy consumption. Look for pumps with high hydraulic efficiency to maximize performance and minimize energy expenses.

Construction and Durability: Consider the construction and durability of the pump. Look for robust materials and solid craftsmanship to ensure longevity and reliability, especially if the pump will be subjected to challenging or corrosive environments.

Maintenance and Serviceability: Assess the ease of maintenance and serviceability of the pump. Look for features such as accessible inspection points, replaceable components, and user-friendly design that facilitate routine maintenance, repairs, and component replacements.

Noise and Vibration: Consider the noise and vibration levels produced by the pump. Pumps with features like smooth operation, balanced design, and noise-reducing technologies can contribute to a quieter and more comfortable working environment.

Manufacturer Reputation and Support: Research the reputation and track record of the pump manufacturer. Look for manufacturers with a history of producing high-quality pumps and providing excellent customer support. This ensures access to technical assistance, spare parts, and warranty coverage if needed.

Cost Considerations: Evaluate the overall cost of the pump, including the purchase price, operating costs, and lifecycle expenses. While it is important to consider the budget, prioritize the long-term cost-effectiveness and reliability of the pump rather than solely focusing on the upfront cost.

By considering these key factors, you can make an informed decision when selecting a big flow double suction pump that best suits your specific requirements, ensuring optimal performance, durability, and efficiency for your application.

Installation and Maintenance of Big Flow Double Suction Pump

The installation and maintenance of a big flow double suction pump are crucial for its optimal performance and longevity. Here are some guidelines to follow:

Installation:

Location: Choose an appropriate location for the pump installation, considering factors such as accessibility, ventilation, and environmental conditions. Ensure the area is well-ventilated and free from excessive heat, moisture, or corrosive elements.

Foundation: Provide a stable and level foundation for the pump. A solid concrete pad or base is recommended to minimize vibration and ensure proper alignment.

Piping System: Design and install the piping system according to the pump’s specifications. Use appropriate pipe materials, sizes, and fittings to minimize friction losses and maintain efficient flow.

Alignment: Ensure proper alignment between the pump and the driver (such as an electric motor or engine). Misalignment can lead to excessive vibration, premature wear, and decreased efficiency. Follow the manufacturer’s guidelines for alignment procedures.

Electrical Connections: Connect the pump to the power supply following the electrical specifications provided by the manufacturer. Adhere to safety regulations and consult an electrician if necessary.

Priming: If required, prime the pump by filling the suction and discharge lines with the pumped fluid or using a priming system as specified by the manufacturer. Proper priming ensures the pump’s efficient operation.

Maintenance:

Regular Inspections: Conduct routine inspections of the pump, checking for any signs of leaks, unusual noises, or vibrations. Examine the pump’s components, including seals, bearings, impeller, and shaft, for wear or damage.

Lubrication: Follow the manufacturer’s recommendations for lubricating the pump’s bearings and other moving parts. Ensure proper lubrication intervals and use the recommended lubricants.

Seal Maintenance: Inspect and maintain the pump’s seals regularly. Replace worn or damaged seals promptly to prevent fluid leakage and maintain pump efficiency.

Impeller Clearance: Monitor and adjust the impeller clearance as specified by the manufacturer. Improper clearance can affect performance and increase wear on the impeller and casing.

Cleanliness: Keep the pump and its surrounding area clean to prevent the accumulation of debris, which can impede performance and cause damage. Regularly remove any dirt, sediment, or foreign particles from the pump and ensure proper filtration in the system.

Performance Monitoring: Monitor the pump’s performance parameters, such as flow rate, head pressure, and power consumption, regularly. Any significant deviations from normal operating conditions should be investigated and addressed promptly.

Service and Repair: Follow the manufacturer’s guidelines for service intervals and recommended maintenance procedures. If repairs or component replacements are necessary, consult qualified technicians or contact the manufacturer for assistance.

It is essential to refer to the specific installation and maintenance instructions provided by the manufacturer of the big flow double suction pump. Adhering to these guidelines will help ensure safe and efficient operation, prolong the pump’s lifespan, and minimize the risk of unexpected failures.

Conclusion

Big flow double suction pump is a versatile and reliable solution that offers efficient high-speed fluid transfer in various industries. Its ability to handle large volumes of fluid and its compact design make it a valuable asset in applications where single-suction pumps fall short.

By considering factors such as flow rate requirements, head pressure, fluid compatibility, efficiency, construction, maintenance, and cost, you can select the right big flow double suction pump for your specific needs. Proper installation and regular maintenance are crucial for maximizing its performance and lifespan.

With its robust construction, extended bearing lifespan, optimized efficiency, and ease of maintenance, this pump delivers exceptional results in industries ranging from mining and power generation to municipal water supply and beyond.

Embracing the big flow double suction pump technology ensures reliable and efficient fluid handling, ultimately leading to increased productivity, reduced downtime, and improved overall performance in your operations. Whether it’s water supply, industrial applications, sewage systems, or firefighting, this pump stands as a trusted solution for handling large volumes of fluid with ease and reliability.

-

WhatsApp

-

E-MailE-Mail:oc@tsbeng.com

-

WeChatWeChat:yychen19